Polyurethane Foam (PUF) panels are widely used in cold storage, clean rooms, prefab shelters, modular houses, and industrial enclosures. Their excellent insulation and durability make them a popular choice. However, the performance of these panels depends heavily on the screws for PUF panels that hold them in place.

The right choice of PUF panel screws ensures structural integrity, weather resistance, and long-term performance. Let’s explore the common types of screws used and how to select the best ones.

Why Screws Matter in PUF Panel Installation

PUF panels consist of a foam core sandwiched between two steel or aluminum sheets. The fastening system must:

- Secure panels firmly to steel or wooden purlins

- Prevent water leakage and thermal bridging

- Resist corrosion in outdoor and humid conditions

- Ensure fast and safe installation

Low-quality screws can cause leakage, rusting, or loosening, which can compromise insulation and structural safety.

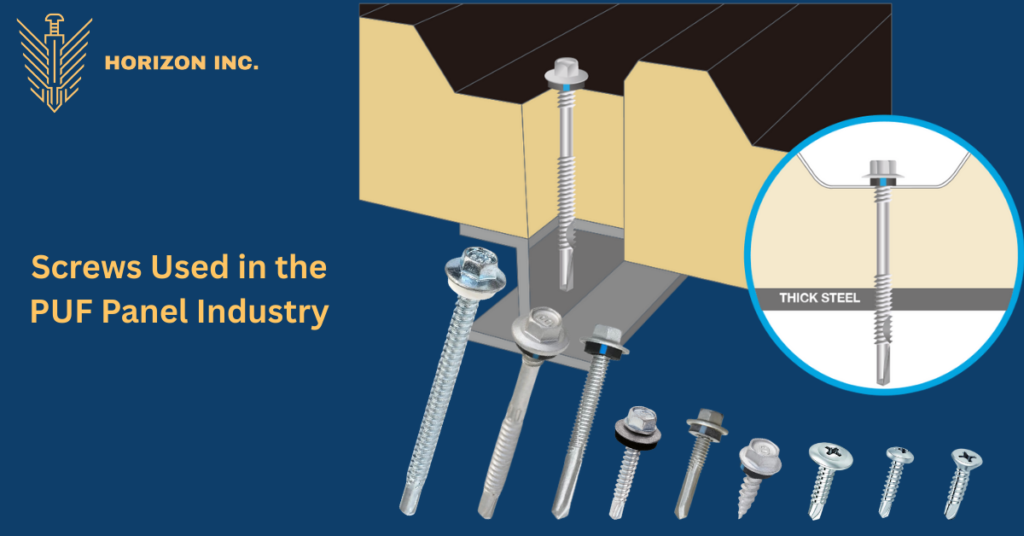

Types of Screws for PUF Panels

1. Hex Head Self-Drilling Screws

The most popular self-drilling screws for PUF panels, used for fixing panels to steel structures and purlins.

- Direct penetration without pre-drilling

- Supplied with bonded EPDM washers for leak prevention

- Zinc-plated or ceramic coated for corrosion resistance

- Strong holding power with fast installation

2. Truss Head Self-Drilling Screws

Ideal for applications requiring a low-profile head.

- Wide head distributes load evenly

- Prevents damage to thin sheet surfaces

- Perfect for overlapping joints and claddings

3. CSK (Countersunk) Self-Drilling Screws

Used when a flush finish is required.

- Head sits flat with the surface

- Enhances aesthetics in cleanroom panels or door frames

- Eliminates protrusions in sensitive applications

4. Stitching Screws (Lap Joint Screws)

Designed for sheet-to-sheet fixing at overlaps.

- Small size (commonly 4.2 mm diameter)

- Prevents water ingress at joints

- Essential for roof and wall cladding connections

5. Long-Length Fasteners

Used for roof panels with thick insulation.

- Lengths up to 250 mm or more

- Strong pull-out resistance

- EPDM washers for long-term weather sealing

Key Considerations When Choosing PUF Panel Screws

- Corrosion Resistance – Choose stainless steel or coated screws for outdoor use.

- Sealing Capability – Always use bonded EPDM washers for leak-proof performance.

- Load Bearing – Select screw diameter and length based on panel thickness and substrate.

- Installation Ease – Self-drilling screws reduce labor costs and save time.

Horizon Inc. – Reliable PUF Panel Screw Supplier

At Horizon Inc., an ISO 9001:2015 certified company, we supply high-quality PUF panel screws sourced from reputed manufacturers. Our fasteners are engineered to deliver:

- Superior drilling and holding strength

- Long-lasting corrosion resistance

- Leak-proof sealing with premium bonded washers

- Multiple head styles and sizes for every application

Whether you are working on cold storage units, cleanrooms, prefab shelters, or industrial enclosures, our screws ensure durability, safety, and efficiency.

✅ Conclusion

The right screws are just as important as the panels themselves. By choosing premium-quality screws for PUF panels, you can ensure faster installation, weatherproofing, and long-term durability of your project.

At Horizon Inc., we provide industry-grade self-drilling, stitching, and sandwich panel screws designed for today’s demanding construction needs.

Contact us today:

📞 +91-9916777262

📧 sales@horizonincindia.com

🌐 www.horizonincindia.com