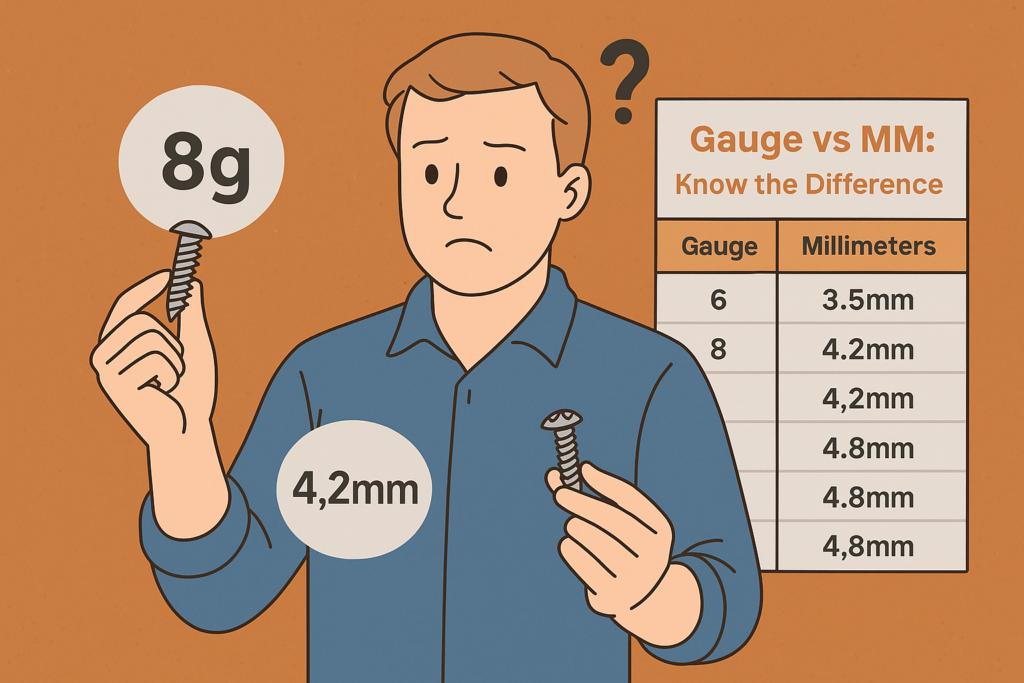

When sourcing or specifying screws, one of the most common sources of confusion is screw gauge sizes. While metric measurements are straightforward (e.g., 3.5 mm), many buyers, technicians, and engineers still encounter gauges like 8g or 10g, especially in products from the UK, USA, or international brands.

This blog aims to demystify screw gauge sizes, provide clarity on how they relate to millimetres (mm) and inches, and help you make better purchasing and engineering decisions.

🔧 What is a Screw Gauge?

The screw gauge refers to the nominal diameter of the screw shaft. Originally based on older wire gauge systems, screw gauges (denoted by “g” like 6g, 8g, etc.) are commonly used in the UK and USA and have been historically tied to manufacturing standards. However, these values do not follow a linear scale—which adds to the confusion.

📏 Why the Confusion?

- A higher gauge number does not always mean a larger screw.

- Metric and inch systems coexist, and both are used depending on industry, region, or manufacturer.

- Screw gauges are used in sheet metal screws, wood screws, self-drilling screws, etc., especially in industries like sheet metal fabrication, construction, and electronics.

📐 Gauge to Millimetre Conversion Table

Below is a handy reference table to understand how commonly used screw gauges translate to their metric and inch equivalents:

| Gauge | Metric Ref. | Inch Ref. Approx |

|---|---|---|

| 0g | 1.5mm | 0.060 |

| 1g | 1.9mm | 0.073 |

| 2g | 2.25mm | 3/32″ |

| 3g | 2.5mm | 0.099 |

| 4g | 2.85mm | 7/64″ |

| 5g | 3.3mm | 1/8″ |

| 6g | 3.5mm | 9/64″ |

| 7g | 3.9mm | 5/32″ |

| 8g | 4.2mm | 11/64″ |

| 9g | 4.5mm | 0.177 |

| 10g | 4.8mm | 3/16″ |

| 12g | 5.5mm | 7/32″ |

| 13g | 6.1mm | 15/64″ |

| 14g | 6.3mm | 1/4″ |

| 15g | 6.5mm | 1/4″ |

| 16g | 6.8mm | 0.268 |

| 18g | 7.5mm | 0.294 |

| 20g | 8.1mm | 0.320 |

| 24g | 9.4mm | 0.372 |

🛠️ Applications and Use Cases

- Sheet Metal Screws: Gauge sizes are commonly used in control panels, enclosures, and cabinets.

- Wood Screws: Frequently specified in gauges.

- Self-Drilling Screws: Often classified by gauge, especially in international specs.

- Fastener Conversion: Necessary when matching international specs in export/import jobs.

✅ Tips for Buyers and Engineers

- Always confirm whether your supplier uses metric or gauge.

- Refer to technical datasheets that mention both mm and gauge.

- When in doubt, use a digital calliper to measure the screw diameter.

- Train your procurement and QC team using conversion charts like the one above.

📥 Downloadable Version

Need this in your hand? Click here to download the chart in PDF.

📢 Have Questions or Need Help Choosing the Right Fasteners?

Contact us at Horizon Inc.

📞 +91-9916777262 | 📧 sales@horizonincindia.com

🌐 www.horizonincindia.com