D-nuts—often called wood insert D-nuts or Type D inserts—are specialised threaded inserts designed to create strong, reusable machine threads inside wood and wood-based boards. Once installed, they allow furniture makers, panel manufacturers, and woodworkers to use standard machine screws or connector bolts without damaging the wood, even after repeated tightening and disassembly.

If you work with MDF, particle boards, softwood, or even dense hardwood, D-nuts are one of the most reliable fastening solutions available today.

Why Use D-Nuts Instead of Wood Screws?

Wood screws rely on cutting their own thread directly into the timber. Over time, especially in softer materials, these threads can strip, loosen, or wear out.

D-nuts solve this problem by introducing a metal thread inside the wood, offering several advantages:

- Greater joint strength within the same footprint

- Consistent tightening torque over multiple assembly cycles

- Reliable engagement with machine screws and connector bolts

- Cleaner, more premium aesthetics, especially in furniture

- Reduced risk of wood cracking or fatigue

This makes D-nuts especially useful in knock-down (RTA) furniture, shop fixtures, cabinetry, and any application where durability and repeatability matter.

Material Matters: Zinc Alloy vs. Steel D-Nuts

Most D-nuts used in woodworking come in two major material options, each suited to different applications.

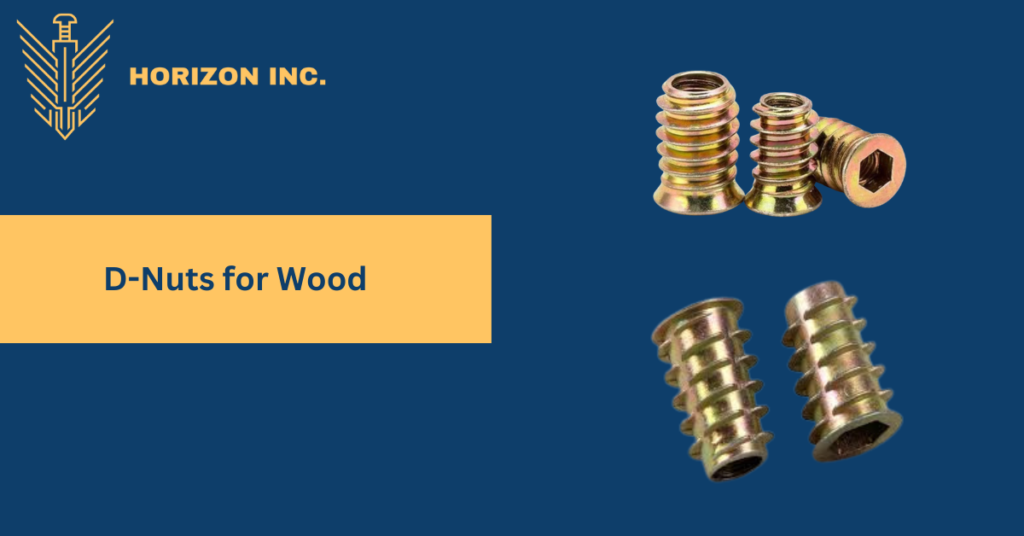

1. Zinc Alloy D-Nuts (Pineapple-Type)

Zinc alloy D-nuts are die-cast components commonly finished in white or yellow zinc plating for good corrosion resistance. These are the most popular choice for furniture and cabinet applications.

Exterior Design

Zinc alloy inserts are easily recognisable by their “pineapple” exterior—a knurled, nodular pattern made up of segmented teeth.

This aggressive geometry:

- Bites deeply into boards like MDF and particle board

- Prevents rotation under load

- Provides outstanding pull-out resistance in softer wood types

Best For

- MDF and particle board

- Plywood and softwood

- Indoor furniture, wardrobes, cabinets

- Modular and knock-down furniture systems

Zinc alloy D-nuts offer fast installation, strong anti-rotation performance, and excellent value for light to medium duty use.

2. Steel D-Nuts (Thread-Type)

Steel D-nuts—made from mild steel or zinc-plated carbon steel—are the choice when mechanical strength is the priority.

Exterior Design

Steel variants resemble a small metal bush with a continuous external screw thread. This threaded profile:

- Cuts cleanly into dense hardwood

- Provides superior axial grip

- Handles higher tightening forces

- Resists long-term loosening and vibration

Best For

- Hardwood such as oak, teak, rubberwood

- High-load or structural joints

- Industrial or commercial furniture

- Jigs, fixtures, and equipment that see repeated tightening

If durability, strength, and fatigue performance are critical, the steel threaded D-nut is the right choice.

Pineapple vs Thread: The Quick Explanation for Customers

When explaining D-nuts, the easiest visual distinction is their exterior:

| D-Nut Type | Exterior Look | Works Best In |

|---|---|---|

| Zinc Alloy (Pineapple) | Knurled, segmented “pineapple” pattern | MDF, particle board, softwood |

| Steel (Thread-Type) | Coarse external screw thread | Hardwood, high-load joints |

Both have internal machine threads (M3–M10 typically), but the outer design determines where each performs best.

Where D-Nuts Are Used

Thanks to their combination of wood aesthetics and metal strength, D-nuts are used across many industries:

● Knock-Down Furniture

Beds, tables, wardrobes, modular cabinets assembled with connector bolts.

● Office & Retail Fixtures

Desks, counters, partitions, displays—especially where rearrangement is frequent.

● Audio & Equipment Cabinets

Speaker boxes, wooden enclosures, and any application requiring vibration resistance.

● Jigs, Fixtures & DIY Projects

Workholding jigs, adjustable stops, repeat-assembly parts, and hobby woodworking.

How to Install D-Nuts Correctly

Getting the best performance from a D-nut depends on proper installation:

1. Drill an Accurate Pilot Hole

The pilot hole must be slightly smaller than the D-nut’s outer diameter for the insert to bite into the fibres.

2. Keep the Insert Proportionally Aligned

Start by hand; most D-nuts have a hex socket to drive them in cleanly and squarely using a hex key or driver bit.

3. Drive Until the Flange is Flush

The integrated flange prevents over-driving and provides a clean seating surface. Avoid over-torquing to prevent wood bulging or cracking.

Production Tip

In manufacturing setups, using a torque-controlled driver with the correct hex bit ensures consistent installation without damaging the substrate.

How to Choose Between Zinc Alloy and Steel D-Nuts

Use this simple selection guide:

Choose Zinc Alloy (Pineapple Design) When:

- The base material is MDF, particle board, plywood, or softwood.

- The application is indoor furniture or medium-duty fixtures.

- You need rapid installation and strong anti-rotation performance.

Choose Steel (Thread-Type) When:

- The wood is dense hardwood or requires maximum pull-out strength.

- The joint will face repeated tightening, mild vibration, or moderate impact loads.

- You are building jigs, industrial furniture, or structural wooden assemblies.

Conclusion

D-nuts may be small, but they play a critical role in modern furniture design and woodworking.

Whether you choose the zinc alloy pineapple-style or the steel threaded style, both types deliver:

- Strong, reliable, reusable threads in wood

- Superior performance compared to regular wood screws

- Long-lasting joints that tolerate repeated assembly cycles

Selecting the right insert for your material and application ensures lasting performance, cleaner finishes, and professional results across all your wood-based projects.

📌 Connect With Us

Need rivets for your fabrication or structural projects?

📞 Call: 080-41179152

📱 WhatsApp: +91 9916777262

✉️ Email: sales@horizonincindia.com

🌐 Visit: www.horizonincindia.com